compressive stress test|compressive strength test on bricks : member club Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using . Resultado da Ib Funcional. Rua Capitão Urias Batista de Avelar, 2951, Arena W10, 14405-217, Franca. Recomendado pelo Booksy. Destaque. Empreendedor.

{plog:ftitle_list}

De acordo com o projeto Mapping L.A. do Los Angeles Times, Hollywood é ladeada por Hollywood Hills ao norte, Los Feliz a nordeste, East. Ver mais

Compressive strength of concrete depends on many factors such as water-cement ratio, cement strength, quality of concrete material, quality control during the production of concrete, etc. Test for compressive strength is carried out .Moreover, compression testing can reveal the material’s behavior under compressive stress, including whether it fails by cracking (brittle failure), deforming plastically (ductile failure), or some combination of the two. Compression testing involves subjecting a material specimen or product to a controlled compressive force until it deforms or fails. The test can be either force- or strain .Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using .

Compressive strength test, mechanical test measuring the maximum amount of compressive load a material can bear before fracturing. The test piece, usually in the form of a cube, prism, .

Compressive strength tests are conducted to determine the maximum stress a material can endure before breaking under compression. On the other hand, tensile stress .

A compressive test measures material properties, from compressive strength to elastic modulus. But it’s more than just numbers. Addressing issues like stress concentration, specimen misalignment, and .

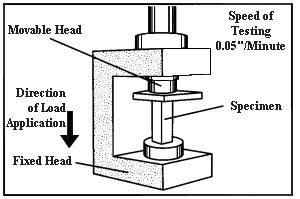

A compression test is conducted in a manner similar to a tensile test except that the force is compressive and the specimen contracts along the direction of stress. Equations (1) and (2) .The goal of compression tests is to detect the behavior or response of materials and obtain the corresponding compressive properties (such as ultimate compressive strength σUCS, yield .

Here are a few additional points to consider about compression testing: Stress-Strain Curve: One of the key outputs of a compression test is the stress-strain curve, which shows how the material deforms in response to the applied . This article will shed light on compression testing and the significance of flexural modulus in assessing material strength. Compression Testing. Compression testing involves subjecting a material to .

Compressive strength testing of concrete:-The test is carried out using 150mm concrete cubes on a Universal testing machine or compressive testing machine. Apparatus. As per IS: 516-1959 Compressive testing machine (2000Kn),15cm×15cm×15cm steel cube molds or Cylinder having Dia 15cm and length 30cm are used.

Behind every effective compressive stress test is a set of robust equipment designed to measure compressive force. Compression testing machines, including hydraulic and servo-electric machines, are the workhorses of this process. Hydraulic machines, composed of single or dual column frames, a load cell, and testing software, can measure .A compression test is a mechanical test that determines how a material such as aluminum or plastics behaves under a compression or crush force. The output of a compression test is a test report that characterizes compressive properties using stress and strain data. Compression tests are commonly used for:The compressive strength is usually obtained experimentally by means of a compressive test where uniaxial compressive load is applied till its failure. Sobolkina et al. [19] investigated the dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix with specimen preparation details shown in Table 1 .

The compressive strength test has multiple objectives, including: To assess the quality of concrete in relation to the specifications for a particular project. To gauge the potential load-bearing capacity of a concrete sample, which helps in .Compressive stress and strain are defined by the same formulas, Equations \ref{12.34} and \ref{12.35}, respectively. The only difference from the tensile situation is that for compressive stress and strain, we take absolute values of the right-hand sides in . Compressive strength is a critical parameter in evaluating the mechanical performance of concrete, serving as a metric of its ability to withstand loads and stresses. Governed by standard C 39/C 39M, compressive strength tests are instrumental in assessing concrete's suitability for various construction applications. Test Methodology Scope

In the compression test, a standardized specimen is loaded under compressive stress until it breaks or until a first crack appears. The testing of materials under compressive stress is carried out in the so-called compression test.Standardized round specimens are used, which are much thicker than tensile specimens.The maximum height of the sample is twice the . Testing is the only way to determine whether a concrete mix has enough compressive strength, or load-bearing capacity, for the intended use. These tests are conducted on cylindrical concrete specimens (per ASTM C39 ) using a machine that compresses the cylinders until they crack or break completely (see Concrete Testing Procedures ).Compressive strength is most often measured by forming 150 mm diameter, 300 mm long (6 inch diameter, 12 inches long) test cylinders and then breaking them at a specified age (typically 28 days) although it can also be performed on specimens of different sizes and origins (such as field cores or the remnants of a flexural test). Compressive testing is a mechanical test used to measure the compressive strength of materials. It requires equipment and standard test methods, including compressive strength tests for concrete and metals. Compressive testing is essential in industries such as construction, automotive, and aerospace to ensure safety and durability.

There are some practical difficulties in performing stress-strain tests in compression. If excessively large loads are mistakenly applied in a tensile test, perhaps by wrong settings on the testing machine, the specimen simply breaks and the test must be repeated with a new specimen. But in compression, a mistake can easily damage the load cell .The compressive strength test of concrete involves a standard procedure that ensures uniformity and accuracy of results. The procedure includes the following steps: Preparation of Test Specimens (Concrete Cubes) The first step in the .Compressive strength is an essential property in structural materials, for example, mortar, which comprises the interacial transtition zone in concrete, stone, and steel, since material design is normally evaluated in terms of the risk of compression failure. In addition the CBM is known as having strength for compression force. Therefore plenty of standard tests exist to measure .- Stress - Strain Typical graph showing compression test: Typical graph showing compression test to rupture: We provide force measurement instruments and materials testing machines for compression testing. .

Compressive strength is defined as the maximum compressive stress that is experienced by the material before its breakdown. It is obtained by dividing the maximum load by the cross-sectional area of the material. Compressive strength is comparatively higher than the tensile strength for both ductile and brittle materials. Compressive strength . Similarly, when using the maturity method on your jobsite to test compressive strength, it is recommended to perform cylinder break tests on day-28 of your concrete’s lifecycle for acceptance .

A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load. A typical machine for compression tests consists of a load cell, a crosshead(s), compression test tools, electronics, and a drive system.It is controlled by testing software used to define .

According to section 19.2.1.3 of ACI 318-19 the specified compressive strength shall be based on the 28-day test results unless otherwise specified in the construction documents. 3- or 7-day test results are used to monitor early strength gain, especially when high early-strength concrete is used. 5.1 Care must be exercised in the interpretation of the significance of compressive strength determinations by this test method since strength is not a fundamental or intrinsic property of concrete made from given materials. Values obtained will depend on the size and shape of the specimen, batching, mixing procedures, the methods of sampling, molding, .compression test) and the flexural tests. The Brazilian Test The test consists of applying diametral compressi on to induce tensile stresses in a thin disc of rock. As shown in Figure 4a, a line load creates a uniform tensile stress across the loaded diameter accompanied with a vertical compressive stress. Failure is assumed to start at the Compression testing is key in materials science for evaluating how materials respond to compressive loads. It helps determine mechanical properties like stiffness, strength, and fatigue life. . Compressive Strength – A material that fails in compression by crushing or fracturing, the compressive strength is the maximum stress (Figure 1 pt D .

Compressive strength is a fundamental parameter that informs the safety, quality and durability of a particular mix of concrete. Testing according to ASTM C39 is central to the QA/QC process. For over 80 years, ASTM C39 has been the industry standard test method for testing the compressive strength of concrete cylinder specimens. In this . The image below shows a visual comparison of before and after testing and how tensile stress impacts a material versus how compressive stress affects it. [IMAGE] Comparing These Stress Types. The main difference between tensile stress and compressive stress is the type of force applied and how the material deforms as a response.If the compression strength or bending strength of a 2-inch by 4-inch beam is not known, deflection due to bearing a load may cause significant deformation, which could even lead to its failure during service life. . which can be determined from a stress test. However, strength properties of hardwood lumber are not that critical because a .

concrete creep test procedure

Preparem-se para uma inundação de novas emoções.

compressive stress test|compressive strength test on bricks